What is Refractory Cement (Fireproof Cement)?

Refractory cement /fireproof cement /fire cement contains high alumina content and other properties that make it gain thermodynamic properties suitable for high temperature conditions. The fire cements are made with minerals like aluminium oxide to bind the coarse aggregates in the cement thereby increasing the thermodynamic properties of the cement, making temperature resistant and good formability.

Castable refractory cement has chemical and physical properties used for creating heat-resistant structures that retain and insulate. Due to their high resistance to heat and thermal shock, you can use castable refractory cement and other products to build kilns and furnaces. Refractory castables can be used to create the monolithic linings within all types of furnaces and kilns.

Applications of Fireproof Cement in Kampala, Uganda.

The application of refractory cement in Kenya include:

- Incinerator walls, fences,

- Barbecues, fire drill areas, pizza ovens and other Industrial ovens

- Sewage and wastewater systems,

- Seaside projects, industrial floors,

- Agricultural buildings, lintels, sealing hinges

- Blast furnace, Foundries, Forge furnace, Tunnel kilns,

- Heat treatment furnace car tops, Electro-phosphorus furnace, Sock pit cover construction etc.

Types of Refractory Cements (fireproof Cement) in Kenya

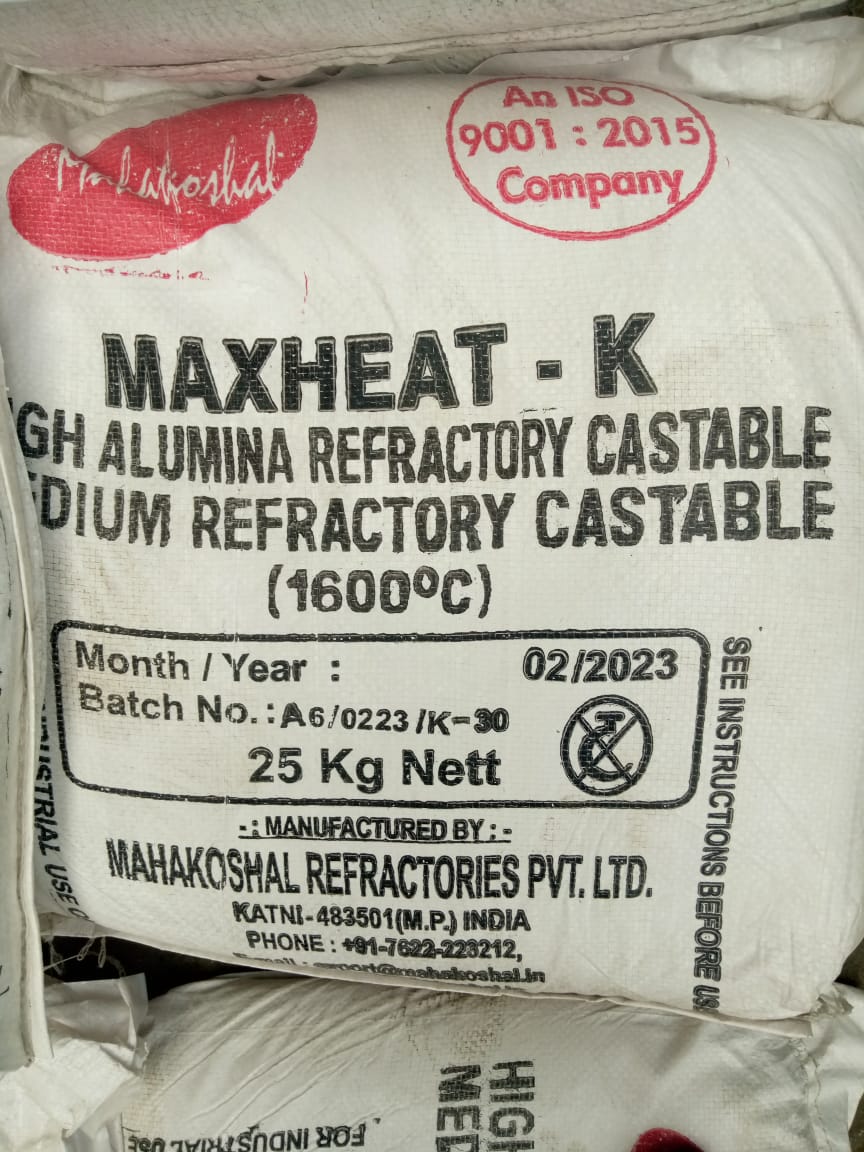

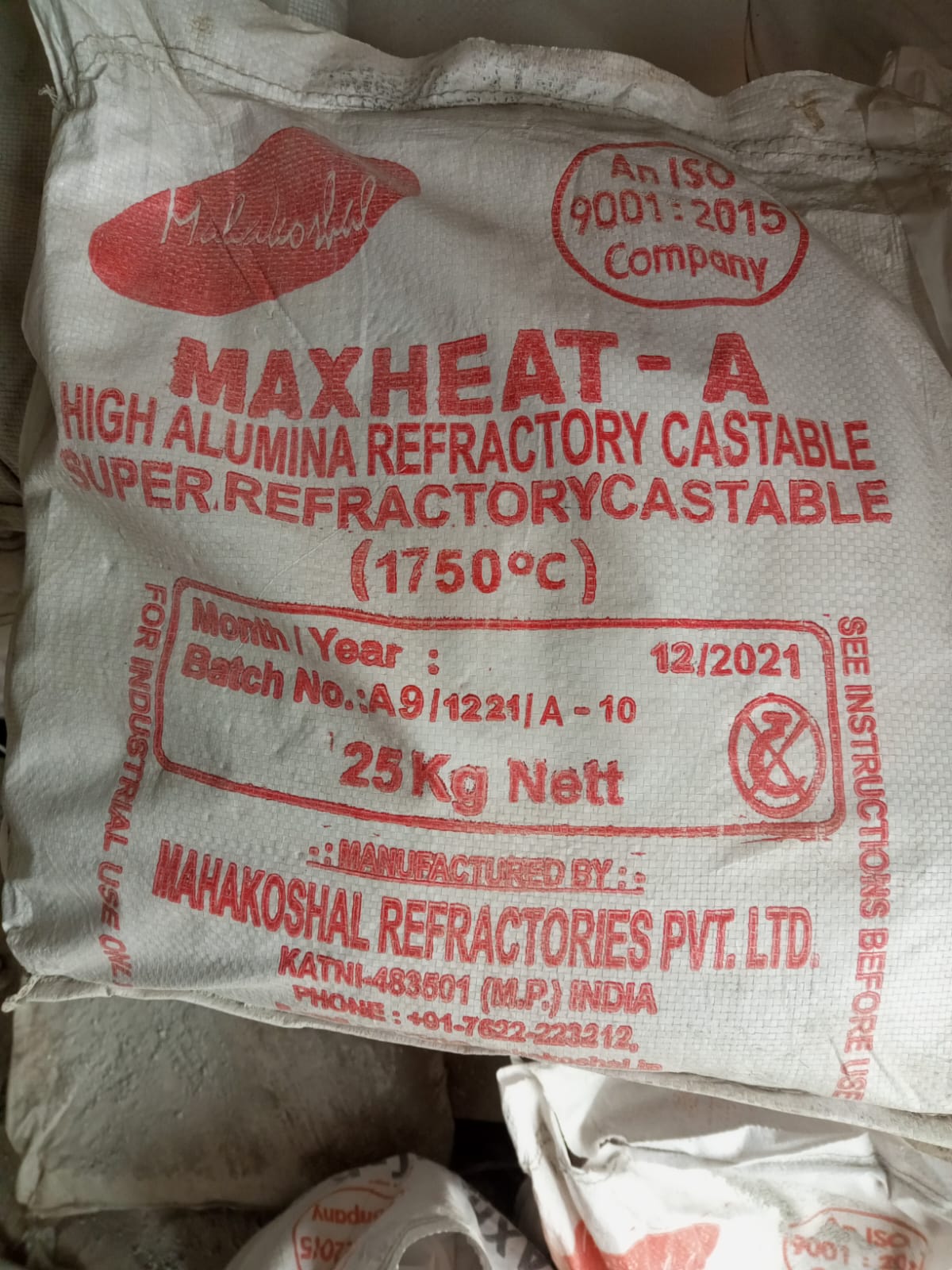

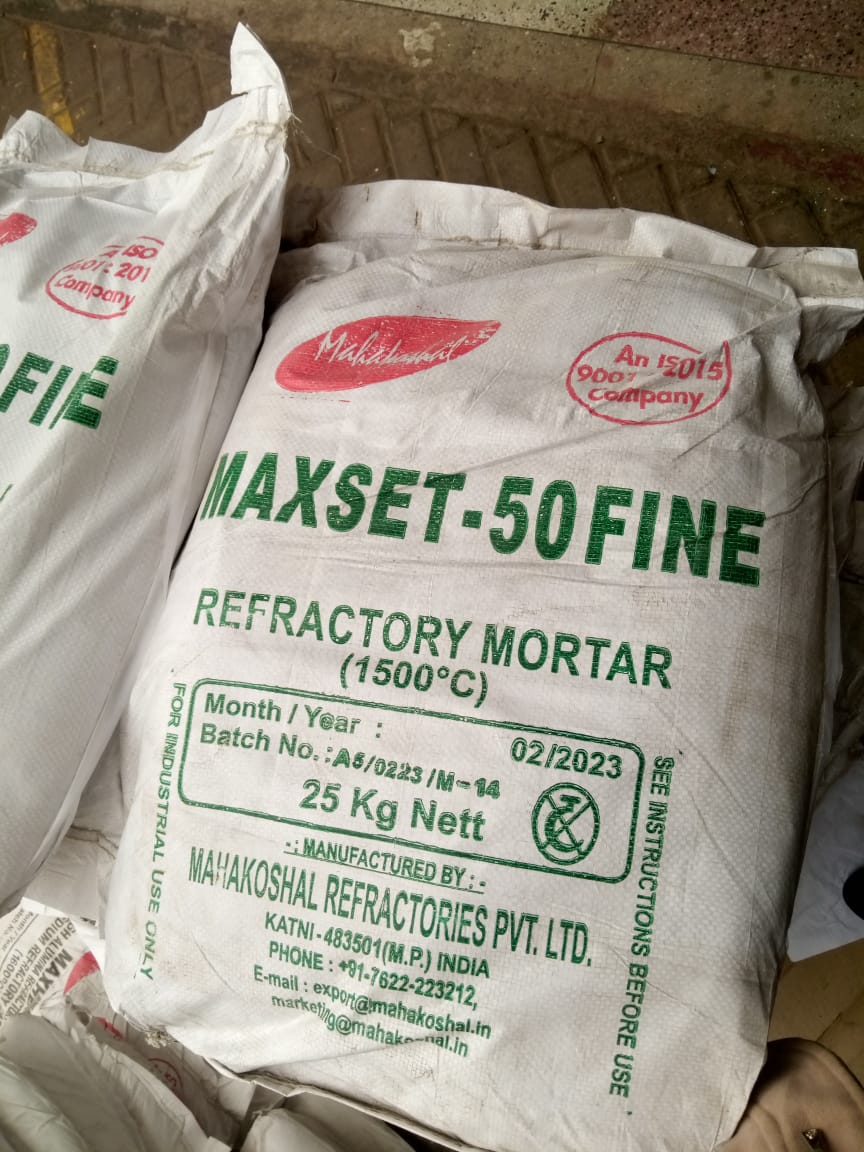

There are various types of refractory cement in Kenya. Citizen Cooling Solutions Limited supplies the 4 main types refractory cement in Kenya. These are Fondu Cement Max50, Maxset 50% Fine (Mortar/Fire Clay), Maxheat K and Maxheat A. The Four types of cement are classified according to their alumina content which determines the range of temperature which they can withstand.